The Engineering Training Center of Zhejiang University gave full play to the university's advantages and professional responsibilities, and assisting Beijing Jingdiao Technology Co., Ltd. completed the technical research and development and small batch trial production of key parts of meltblown equipment.

Beijing Jingdiao Technology Co., Ltd. is a national high-tech enterprise established in 1994 focusing on the research and development and manufacturing of CNC machine tools. It has more than 4,900 employees and an annual output value of 4 billion yuan. The number of customers exceeds 10,000. It was awarded the "China "Top 100 Machinery Industry Enterprises" title. The Engineering Training Center of Zhejiang University and Beijing Jingdiao Technology Co., Ltd. jointly established a CNC joint laboratory in October 2013 and established a long-term strategic partnership.

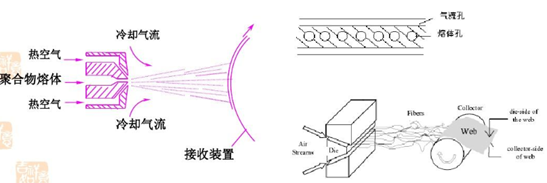

Melt-blown equipment is a device that uses melt-blown non-woven technology to produce melt-blown cloth. The process is to use high-speed hot air to draw the polymer melt stream extruded from the die nozzle hole to form ultra-fine fibers, condense on the net curtain or roller, and rely on self-adhesive to become a non-woven fabric. Melt blowing process: polymer preparation→melt extrusion→metering pump→melt blowing die assembly→melt trickle stretching→cooling→receiving device. Main equipment: feeder, screw extruder, metering pump, melt blown die assembly, air compressor, air heater, receiving device, winding device. Production auxiliary equipment mainly includes die cleaning furnace, electrostatic application device and spray device.

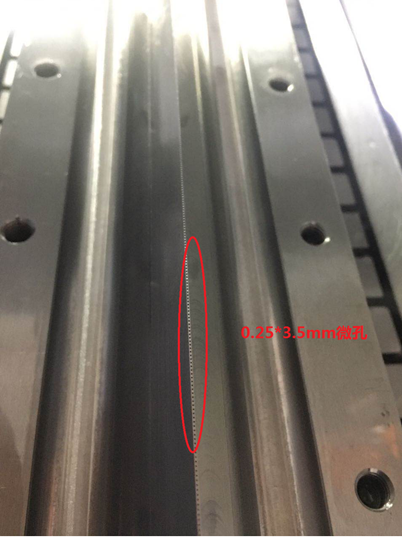

The key component of the melt-blown equipment is the melt-blown die assembly, which is composed of a spinneret, an air plate, and heating and heat preservation elements. The spinneret is a key part, and the spinneret holes are often arranged in a single row. The diameter of the spinneret is generally φ0.1-φ0.4mm, and the depth ranges from 2.5-4mm according to product requirements. The processing requirements are extremely hard to be met with.

The materials for the trial-produced parts in the Engineering Training Center are divided into two materials: W1.2344 die steel and S136 stainless steel. The hardness of the material is generally between HRC32-36, and the hardness of some materials is above HRC42. Under the above-mentioned harsh conditions, it is finally necessary to uniformly process 901 small holes of φ0.25mm on a plane of 600mm*0.6mm, with a hole depth of 3.2mm, and it is required that there should be no broken tools in the continuous processing of 901 holes.

Finally, through the joint application technology development of the engineering training center and enterprise engineers, the JDVT600T_A13S equipment produced by Beijing Jingdiao Group was used on site to successfully complete the trial production of spinnerets of various specifications. The subsequent two parties will also discuss the φ0.2mm/φ0.1mm aperture. Of spinneret products continue to carry out technical research and study.